THE FUTURE OF NANOENCAPSULATION

Complete technology solutions for high quality GMP nanoparticle manufacturing

At the forefront of advanced lipid (LNP) and polymeric nanoparticle (PNP) manufacturing, we’ve engineered cutting-edge technology that redefines precision and performance in nanoparticle production.

At the core of our innovation is the proprietary FR-JET® modular mixer, setting a new benchmark for control, efficiency and reliability.

Designed for speed, scalability, and performance, our solutions enable the fastest route from discovery to commercial manufacturing. Whether for small scale R&D batch or full-scale GMP production, our systems deliver consistent, high-quality particles every time.

We empower pharma, biotech, and CDMO partners to accelerate the development of next-generation therapeutics to bring advanced therapies closer to patients worldwide.

Our equipment

Optimized early stage research and screening

-

Dimensions*:

approx. 40 x 50 x 40 cm -

Total flow rate:

up to 100 mL/min -

Batch size::

0.5 - 20 mL

Fast & simplified process development

-

Dimensions*:

approx. 45 cm x 60 cm x 45 cm -

Total flow rate:

6 - 500 mL/min -

Batch size::

no upper limit (continuous)

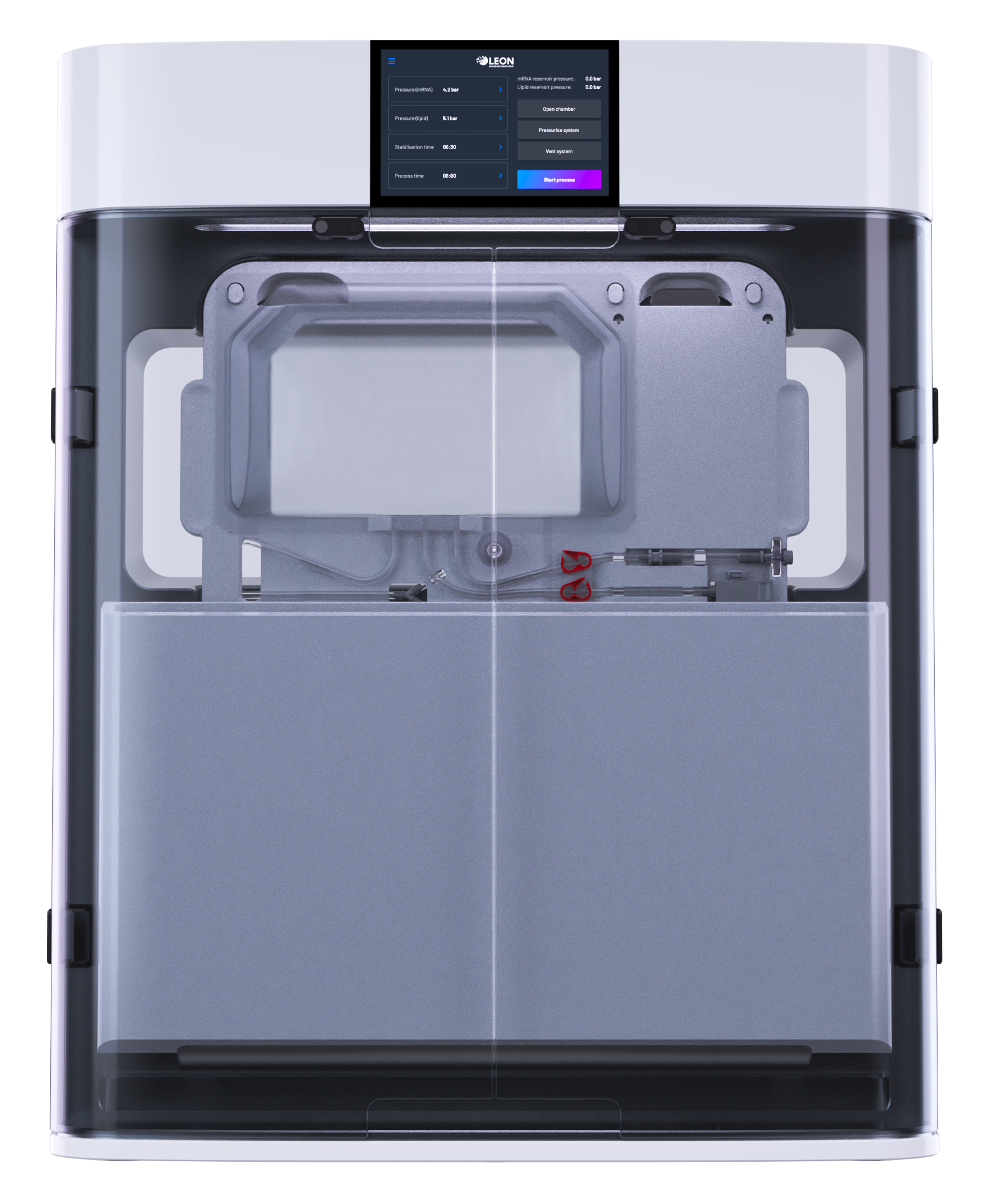

High throughput GMP small to mid- scale sterile batches

-

Dimensions*:

approx. 70 cm x 45 cm x 90 cm -

Total flow rate:

20 - 240 mL/min -

Batch size::

200 - 1200 mL

High volume commercial GMP sterile batches

-

Dimensions*:

approx. 2.4 m x 1.0 m x 2.2 m -

Total flow rate:

<1200 mL/min -

Batch size::

no upper limit (continuous)

*All dimensions are width x depth x height